With an increase in data transfer speed requirements due to the cloud and HD video technologies. The ability to transfer data as efficiently as possible remains the driving force in today’s communication age. The backbone of most modern digital information systems is increasingly implemented using fiber optic networks, with a growing focus upon the MPO fiber connector. The MPO connector was designed to easily interconnect multiple fiber strands and transfer an ever increasing amount of data. While the MPO connector was originally created in the late 20th century. Refinements to the original design have resulted in a much higher performance product. The MTP fiber connector manufactured by US Conec® is the most prominent and enhanced multifiber connector available today.

MTP Cables (including Ultra Low-Loss MTP® Elite), connectors and adapters offer significant enhancements. Because they are fully compatible with the generic MPO fiber cable connector. Therefore can be interchangeably utilized in any network design.

Typically, a multifiber connector terminates an 8-144 strand multi-fiber ribbon in an integrated connector. The two types of connectors, Non-Pinned (Female) and Pinned (Male) can be used to join multiple MPO MTP cables using MPO Adapters. They may also be used to terminate multi-fiber links on a cassette in a fiber optic patch panel. OptoSpan also offers a range of MTP Breakout Cables to individually route each fiber optic strand.

Figure 1. Deconstruction of MTP Fiber Connector

The following section lists the technical improvements between the original MPO design and the modern MTP design. Enhancements in guide pins, spring, and ferrule design makes MTP a better connector with less signal loss in comparison to the standard MPO design.

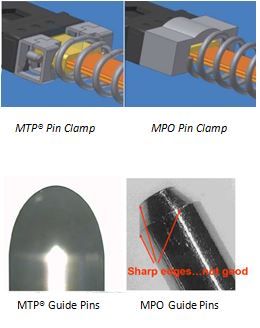

1. Guide Pins

In all connectors, the guide pins are designed to accurately guide the mating of two connectors to form a physical connection.

The MPO connector have been manufactured using an inferior plastic pin clamp. Which may lead to effortless breaking of pins with constant cable mating.

OptoSpan Fiber Optic Cables along with US Conec MTP connectors, provide the benefit of having guide pins attached to a recessed metal pin clamp. Ensuring a strong clasp on the pins and minimizing any inadvertent breaking when mating the connectors.

The pins on a standard MPO connector were designed with sharp edges which result in gradual damage to the mating connector.

The redesigned pins contained within MTP fiber connector have elliptical edges. Allowing for nearly no damage between mating connectors.

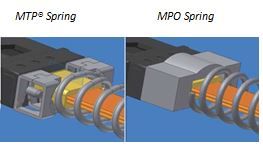

2. Spring

The spring contained within the connectors was implemented with the goal of maintaining the adequate force required to establish a constant physical connection when two connectors are mated.

The MPO spring to the left can be found in an MPO connector. Due to being unsecured it may accidentally cause damage to the fiber ribbon.

Refinement of the spring design has improved reliability by constraining the spring and modifying it from a circle to an oval shape (as seen in MTP® Spring above). Accommodating the width of the fiber ribbon and minimizing any chance of internal damage when mating. Aside from internal damage protection, OptoSpan also offers Armored MTP Cables to further shield a network from external damage.

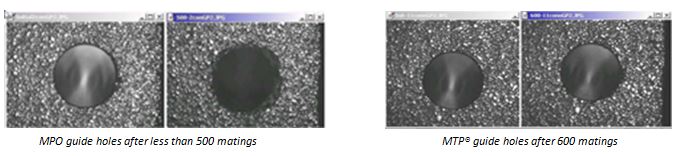

3. Ferrule

Within these connectors, the ferrule is the component which surrounds the fiber strands and maintains their position throughout the physical connection.

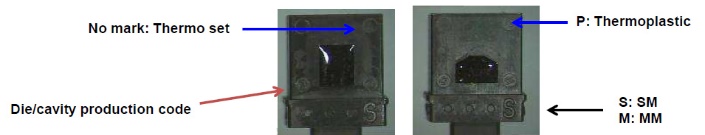

The original compound used in the MPO connector to mold the ferrule was thermo set. A material which when exposed to varying temperatures may change in shape and thus alter the diameter of the guide holes when mating.

MTP fiber connectors have been improved to use ferrules molded from thermoplastic. Which has proven to be much more resilient to varying temperatures. The new material maintains a constant diameter for the guide holes. As a result, it creates more reliable physical connection.

In order to provide the highest quality networking components. OptoSpan, in partnership with US Conec®, proudly offers the most versatile and complete MTP® solution. The previously mentioned advantages of the US Conec MTP optical connector. Paired with the quality of OptoSpan Fiber Optic Cables. Provides a high performance connection with rock solid network reliability. All OptoSpan MTP fiber optic cables offer the following:

• Genuine and complete MTP fiber connector assembly by US Conec®

• Every cable assembly is documented with a unique serial number and test report.

• Entirely assembled and tested in an ISO 14000 (Class 7) quality controlled clean room.

• All cables have been manufactured using US Conec® provided equipment.

• Accommodation of any client required alterations, ensuring the required polarity and configuration.

MTP®, MTP Elite® are registered trademarks of US Conec®